- +86-15913803231

- goochain@goochain-tech.com

The DC 2.35mm to Dual 2.0mm Electrode Pin Medical Cable is designed for TENS, EMS, and physiotherapy equipment used in rehabilitation and electrotherapy applications. This medical lead wire features a 2.35mm DC plug to dual 2.0mm electrode pin connectors, providing stable signal and power transmission between the electrotherapy device and electrode pads. The cable includes three adjustable sliders for easy cable management, helping users keep the lead wires organized during therapy sessions. Manufactured using medical-grade materials, the cable ensures durability, flexibility, and patient safety

The Φ3.5mm medical female snap button is a precision-engineered connector designed for medical electrodes, ECG cables, and patient monitoring accessories. Manufactured from high-quality brass with nickel plating, it offers excellent conductivity, corrosion resistance, and long-term durability for medical applications.

The 3.5mm 5-Pole Audio Male to Open 5-Core Cable is designed for high-fidelity audio transmission in electronics, communication devices, and professional audio equipment. With five separate cores, this cable allows independent connection for audio signals, microphones, and control channels.

The 3.9mm Stainless Steel Male Snap Button Connector is a precision-machined medical-grade component designed for reliable electrical connection in ECG, TENS, EMS, and other physiotherapy or monitoring devices. Manufactured using high-quality stainless steel, this snap button offers excellent conductivity, corrosion resistance, and long-term durability. It is widely used in medical electrode pads, ECG lead wires, wearable monitoring devices, and rehabilitation equipment.

This 9.0mm magnetic snap to 4.0mm banana female medical cable is designed for reliable signal transmission in medical and physiological monitoring applications. The magnetic snap connector allows quick and secure connection, while the 4.0mm banana female connector ensures stable compatibility with medical devices and patient monitoring equipment.

This USB Type-C to SHR-05V-S-B cable is designed for secure and stable signal and power transmission in industrial and embedded applications. Featuring a USB-C male connector with dual screw locking and a 5-pin JST SHR terminal, the cable ensures reliable connection, strong mechanical retention, and long-term durability.

Our Custom Ear Clip Electrodes with 2.0 round tube cables are designed for seamless integration with Vagus Nerve Stimulation (VNS), Transcutaneous Auricular Vagus Nerve Stimulation (TAVNS), and Transcutaneous Vagus Nerve Stimulation (TVNS) systems. Manufactured in China, these high-quality electrodes ensure safe, effective, and long-lasting use in nerve stimulation therapies. Ideal for healthcare providers and medical device manufacturers, they are a trusted choice for precision and reliability in neuromodulation.

The tVNS Vagus Nerve Ear Clip to DC 2.35mm Connector Cable is a medical-grade connection cable designed for transcutaneous vagus nerve stimulation (tVNS) systems. It connects auricular ear clip electrodes to tVNS stimulation devices equipped with a DC 2.35mm output interface, ensuring stable signal transmission for non-invasive neuromodulation applications.

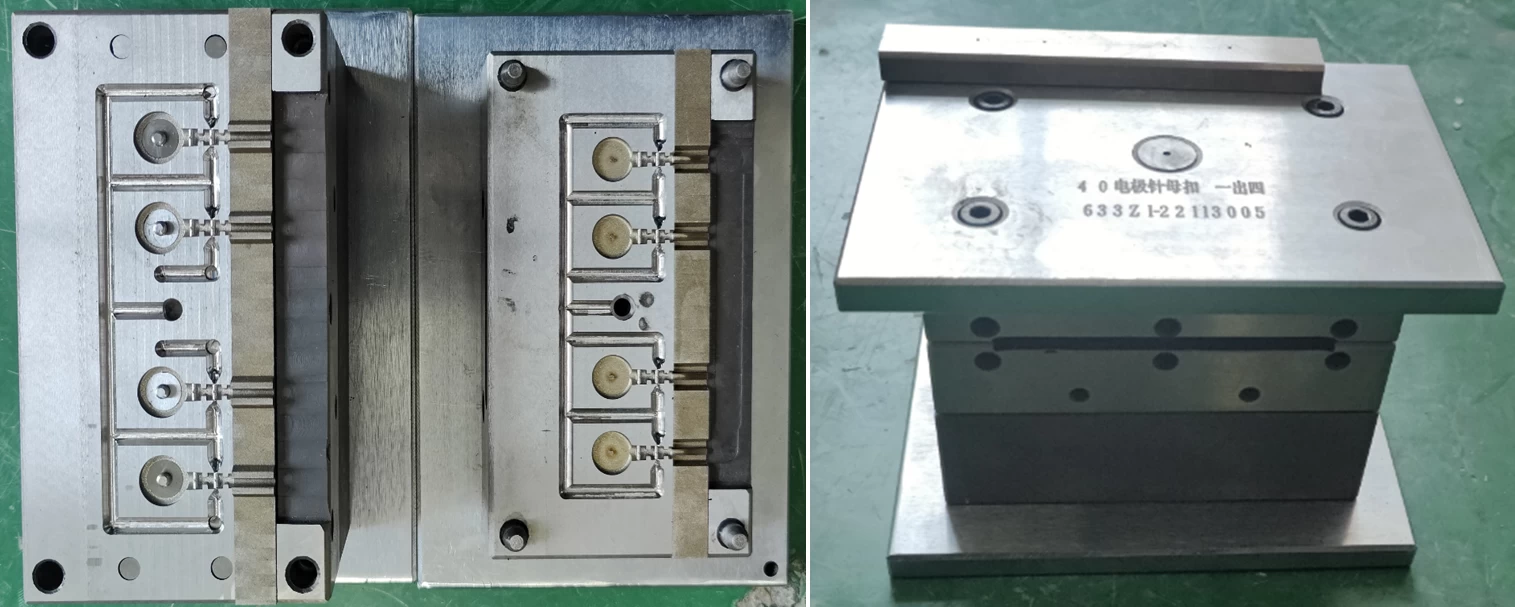

We usually see USB Cable assemblies of various shapes and directions for the connector head. Do you know that these shapes are all injection molded by metal molds? Let us learn about the molds for the production of USB data cables today!

First of all, let's understand the classification of plug / connector molds! Common plug molds include USB connector, DC plug, AC plug, audio plug, Medical electrode connectors, Ethernet RJ45 RJ50 Connectors, Pogo pin magnetic plugs, etc.

First of all, let's understand the classification of plug / connector molds! Common plug molds include USB connector, DC plug, AC plug, audio plug, Medical electrode connectors, Ethernet RJ45 RJ50 Connectors, Pogo pin magnetic plugs, etc.

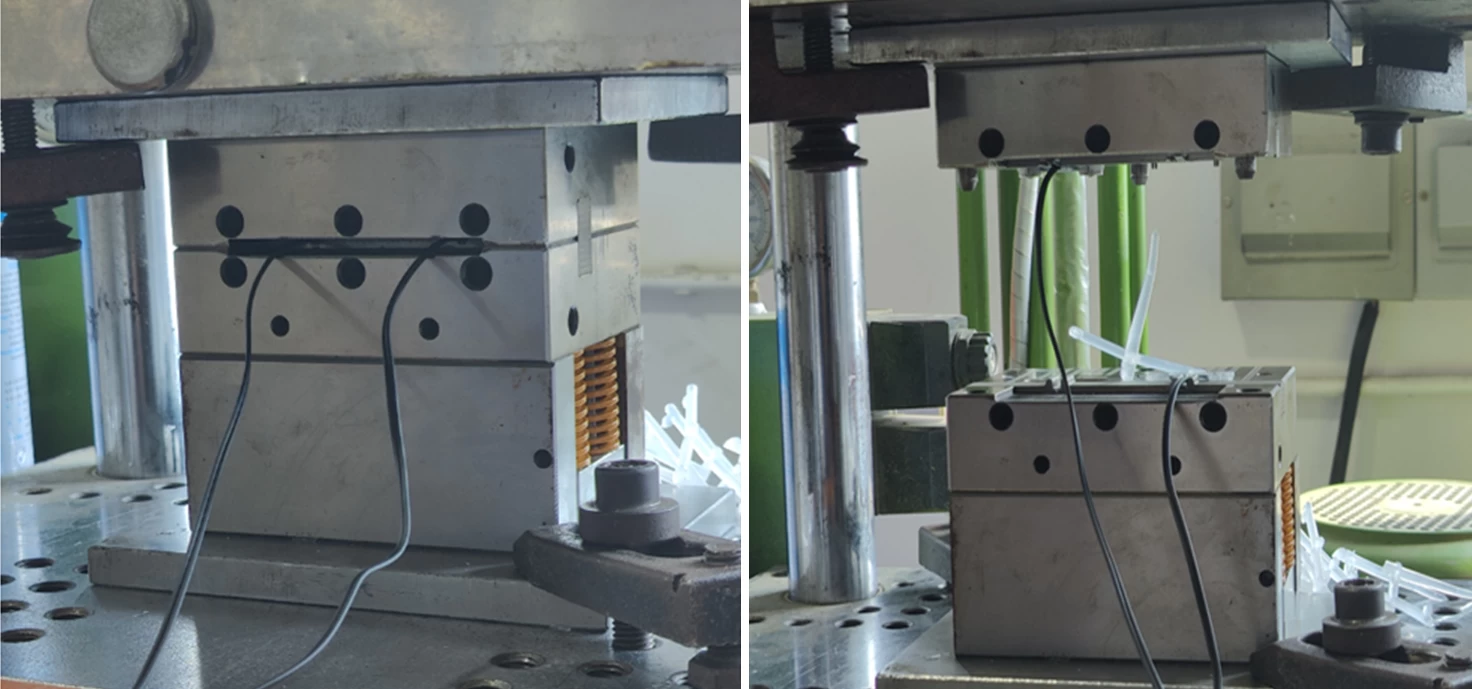

Goochain as a professional custom cable assembly factory who has a strong team of engineers who can provide drawings and quotations for customer development and design. When the customer confirms the plan and places an order, our mold can be put into production immediately, and the production cycle of the mold is generally 5-10 days! At this point, you may have to ask why the delivery time is so different, because the mold structure and the number of Caves of different designs will directly affect the production time of the mold, such as some relatively simple prototype molds or conventional USB molds, the production time will be relatively fast Some are generally available in 5-7 days; however, for some special elbow designs and complex design product molds, the production time will take about 10 days; after the production of these molds is completed, our sample engineers will erect them on the injection molding machine, Test the mold for the customer to ensure that the mold meets the standard and make a sample of the cable assemblies to the customer for confirmation and mass production!

Simple Push mold:

Features: low cost, short lead time for mold, suitable for products with small quantity orders or customers who need to verify the sample structure first

Disadvantages: Number of caves for the mold is less, and it cannot be fixed to the injection molding machine, but the mold can only be moved manually, and the production efficiency is low during mass production, resulting in increased production costs.

Fixed Molds:

Features: There are many mold cavities, and the upper and lower molds of the mold can be firmly fixed on the injection molding machine, reducing labor to realize automatic mold opening of the machine, improving batch production efficiency, and long service life of the mold.

Production equipment and process display: