- +86-15913803231

- goochain@goochain-tech.com

Goochain offers fully customizable electrode test hook cables, ideal for use in medical devices, diagnostics, and electronic test applications. This product combines a TO 2.0 electrode needle with an insulated protective sheath wire, ensuring safety, precision, and durability.

This USB A Male with Ferrite Core to 4 Pin Terminal Connector Cable is designed for reliable data transmission and stable power supply. Equipped with a ferrite bead to reduce EMI/RFI interference, it is ideal for industrial equipment, medical devices, and customized electronic applications.

This 45W USB-C PD Wall Charger is the ideal solution for frequent travelers and business professionals who need a compact and versatile charging solution for their devices. Featuring interchangeable EU, UK, and AU plug adapters, this charger is designed for global compatibility. The USB-C Power Delivery (PD) technology ensures faster and more efficient charging for a wide range of devices, including laptops, smartphones, and tablets. Its compact and lightweight design makes it easy to pack and carry, while the high-quality material ensures safety and durability during use.

This USB-C Charging Stand with a Pogo Pin Connector is designed for rugged tablets and handheld devices that require reliable, high-cycle, fast charging. The magnetic pogo pin design ensures secure docking with minimal wear, ideal for industrial and commercial environments. Built in our Dongguan, China factory, this stand is available with full OEM/ODM customization.

The Right Angle USB 3.0 AM to AF Extension Cable with Dual Screw Holes is designed for secure panel mounting and stable data transfer. Featuring a 90-degree USB male connector and a female connector with screw mount design, this cable is ideal for industrial, automotive, medical, and embedded system applications.

Our Silicone LED Light Therapy Mask is a high-quality phototherapy beauty device designed for skincare treatment. Made from medical-grade silicone, this mask offers multiple light colors (red, blue, green, etc.) to target different skin concerns such as acne, wrinkles, and skin rejuvenation. With OEM & ODM customization options, and backed by ISO 13485 & ISO 9001 certifications.

This custom RJ12 to DB9 and PowerUSB 12V cable is specifically designed for POS systems, barcode scanners, receipt printers, and other commercial retail hardware requiring reliable data and power connections. Manufactured by a professional cable factory in Shenzhen, China, this integrated cable solution streamlines connectivity with a 3-in-1 design, minimizing cable clutter and ensuring stable performance. Perfect for OEM integration, large-scale POS installations, and system integrators. Custom length, pinout, and branding available for wholesale buyers and international partners.

The USB Type-C Male to USB Type-C Male Coiled Cable is designed for flexible and space-saving connectivity. Its coiled design minimizes tangling, making it ideal for mobile workstations, vehicle-mounted devices, and environments where cable length needs to adjust dynamically.

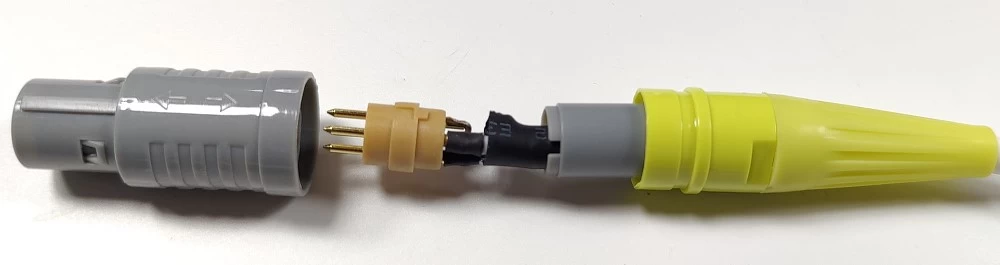

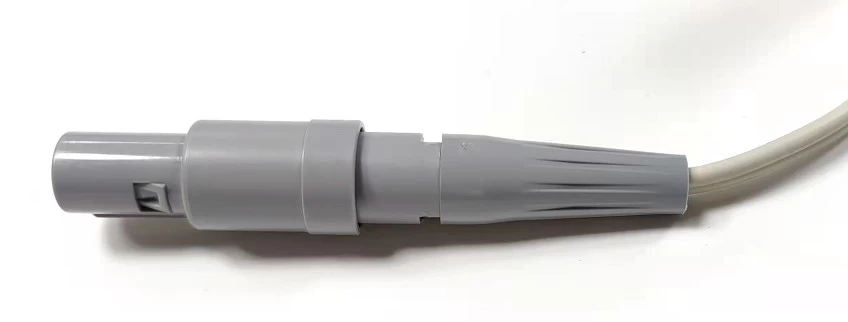

The LEMO connector uses a combined structure design, which can flexibly meet various use requirements, is suitable for high-density installation, saves space, and the plug-in operation is simple, fast and safe. Pulling the cable will not cause the plug to fall off the socket.

It is absolutely safe and reliable after the vibration and electric shock test. All metal parts are processed by precision machining, and the contacts of the pin core are all gold-plated. : Plastic, stainless steel, brass alloy housing, aluminum, etc. The appearance of the product is beautiful and generous, which helps you to improve the grade of the product

Widely used in medical products, mainly in analytical machines, process instruments, dental equipment, other equipment (sensors, catheters), electrosurgery equipment, pacemakers and hearing aids, patient monitors, portable or home equipment, scanning Instrument, sterilization equipment UL60601, sleep instrument, monitor, respirator, ultrasonic therapy instrument, micro drill, nuclear magnetic resonance, blood pump, defibrillator, ventilator, X-ray machine, operating bed, signal connection and transmission

Goochain LEMO lead wire product features introduction

Connectors: original or domestic high-quality connectors are used according to customer needs

Cable and wire material: medical grade TPU flexible double-shielded wire material is used, which has the characteristics of anti-interference, bending resistance, softness, etc.

Production process: Sleeves are used to isolate the welding pins to prevent short circuits, and the tail of the plug is protected by a folding protective sheath or integrated injection molding.

Increase product firmness, reliability, and longer service life

Customization: Quickly customize production according to customer requirements, with diversified materials and styles for customers to choose

Quality assurance: 100% full inspection, Taiwan precision cable testing machine, rest assured and safe to use

Environmental protection requirements: in line with ROHS, REACH standards, in line with all requirements of reliability and various electrical tests